Classificazione

CONTATTACI

INDIRIZZO:

1-1009, parco nazionale di progettazione industriale, strada di No. 599 Jianzhu, Binhu, Wuxi, Jiangsu, Cina, 214062

TELEFONO:Tell: +86 21 51096910

EMAIL:

Email: info@welsobio.com

Inchiesta

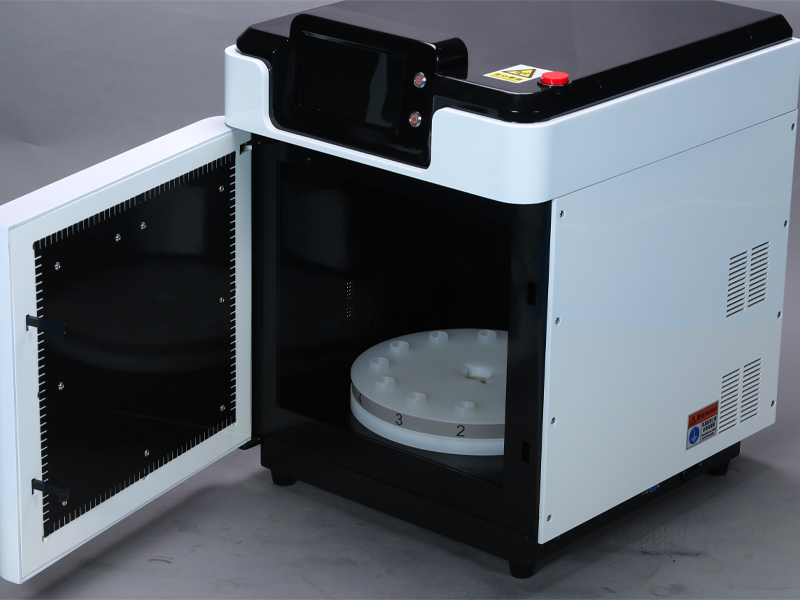

Sistema di digestione a microonde

Dettagli del prodotto

Description

Welso WMD600 series is a hot-selling microwave digestion system, which has been newly designed and upgraded to have higher performance and safer protection system. It is standard equipped with non-contact mid-infrared scanning temperature measurement system, adopts high-precision platinum resistance temperature control system, and adopts non-contact full-tank optical fiber scanning pressure control system. The machine adopts 316L industrial stainless steel structure design, internal spraying multi-layer PFA coating, to meet the impact resistance, anti-explosion, anti-corrosion and other multi-dimensional requirements.

Features

-Robust Industrial Chamber

●316L industrial stainless steel, higherdurability and safety.

●Multi-layer PFA coatings, acid and alkaliproof, longer service life.

-Large Data Storage

● 8 kinds of digestion methods preinstalled.

●Up to 255 groups of digestion method can be created and stored; each method can set up 10 steps.

-Higher Safety Protection

●System auto stops running to trigger safety protection scheme if following situations happen.

*System error *Abnormal sound *No digestion vessel loaded *Door unclosed *Over-temperature or over-pressure.

-Contactless Pressure & IR Sensor

●2 sets of pressure sensors

●1 set of IR sensor with special waveband, much more accurate and safer.

●360 degrees scan monitoring, every digestion vessel can be monitored.

●Vessel quantity is optional.

●6/8/10/12 positions of sample rotors are available to meet various requests.

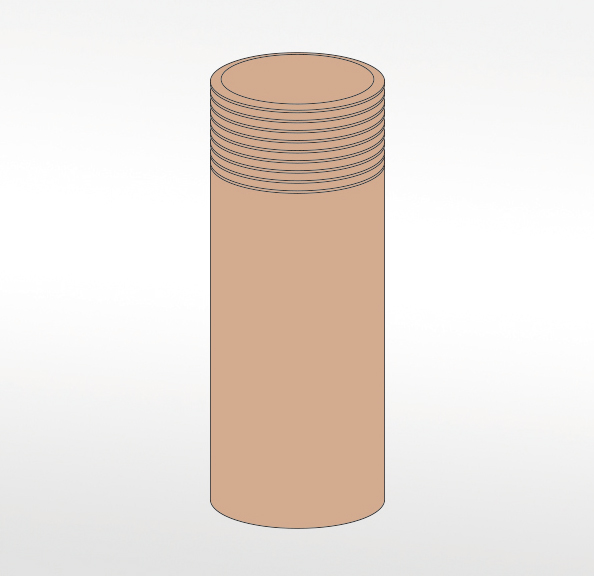

Digestion Vessels

The instrument features a double-ended screw design that ensures good airtightness. The inner vessel is made of imported TFM material. The outer tank is made of PEEK mixed fiberglass material, with great toughness and rigidity toughness and rigidity.

This guarantees the product's safety and reliability during repeated use at high temperatures and pressures over the long term.

The outer vessel is designed based on the 3D directional explosion-proof theory with vertical blasting. In case of explosion, the pressure will release vertically to ensure safety.

The vessel has successfully passed both the pressure resistance test and the simulated intensify test (set 230℃ and keep for 45 mins for over 100 times). Despite these extreme conditions, the tank showed no deformation or breakage and is currently functioning well

Batch Processing Volume

Up to 12 vessels with optional 6, 8, 10 or 12 vessels for easy batch processing.

Programming

The touch screen displays real-time temperature, pressure, and other parameters, providing a clear overview of the digestion process.

meanwhile, it can edit save digestion methods, and use the methods at any time.

Technical Specification

| Model | WMD600 | WMD800 | WMD1000 | WMD1200 |

| Vessel Quantity | 6 | 8 | 10 | 12 |

| Temperature Monitoring Syst em | Temperature Monitoring: Contactless IR Sensor; Scan monitoring for each vessel Temperature Controlling Range: 50~400℃; Temperature Accuracy: +0.1C; Display Accuracy: ±0.1℃ | |||

| Pressure Monitoring System | Pressure monitoring: Contactless Sensor; Scan monitoring for each vessel Pressure Controlling Range: 0~15MPaPressure Accuracy: ±0.01MPa Display Accuracy: ±0.01Mpa | |||

| Vessel Volume | 100mL | |||

| Sample Vessel Material | Imported TFM | |||

| Protection Vessel Material | Peek+Glass Fiber | |||

| Display | 7 inch Touch Screen | |||

| Rotation | 360°Continuous Rotating | |||

| Microwave Tank | 316L Stainless Steel tank With Corrosion-Proof Coating | |||

| Microwave Power | 0-1000W(Adjustable) | |||

| Microwave Leakage | <5mw/cm² | |||

| Air Exhaust | High Power Corrosion-Proof Air Blower | |||

| Power | AC220V±10%, 10A, 50/60Hz | |||

| Dimension | 490*560*630mm(L*W*H) | |||

| Weight | 47KG | |||

Raccomandazioni correlate

Segui il conto ufficiale